Sandst4rm

Active Member

- Joined

- Jul 10, 2018

- Messages

- 195

- Reaction score

- 184

- Points

- 43

- Location

- South Australia

- Members Ride

- VT S1 Calais Ecotec - VP Ute 3800

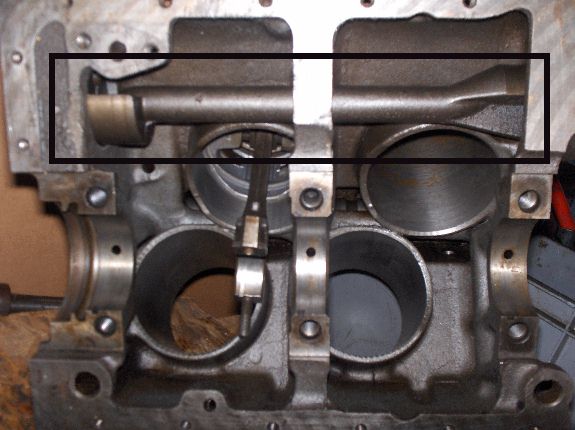

Hey all, just got my big series 1 back from the machine shop.

Balanced rotating assembly with 040 pistons rings and Spool H beam conrods. New balancer and they did something to the flex plate i think.

I asked them to replace the balance shaft bearings am unsure if they did or not cause it wasent on the invoice HOWEVER.

If i fit the balance shaft like i want to. (I dont think they modified it in any way) wont it make the balance WORSE? Since the overall weight of the rotating assembly has changed???

Balanced rotating assembly with 040 pistons rings and Spool H beam conrods. New balancer and they did something to the flex plate i think.

I asked them to replace the balance shaft bearings am unsure if they did or not cause it wasent on the invoice HOWEVER.

If i fit the balance shaft like i want to. (I dont think they modified it in any way) wont it make the balance WORSE? Since the overall weight of the rotating assembly has changed???