Ok, now I have some progress to talk about

Got the block back from the machine shop, was a bit disappointed they hadn't touched the mains as I specified I wanted them line honed. The guy at the machine shop was confident that I wouldn't need to as they measured up good and suggested I do a pre-assembly and bring the block back if it isn't right. I'd need to bring the block back to do the deck as it also hasn't been cut yet. This is because I need to measure piston height before I know how much of the deck to cut back.

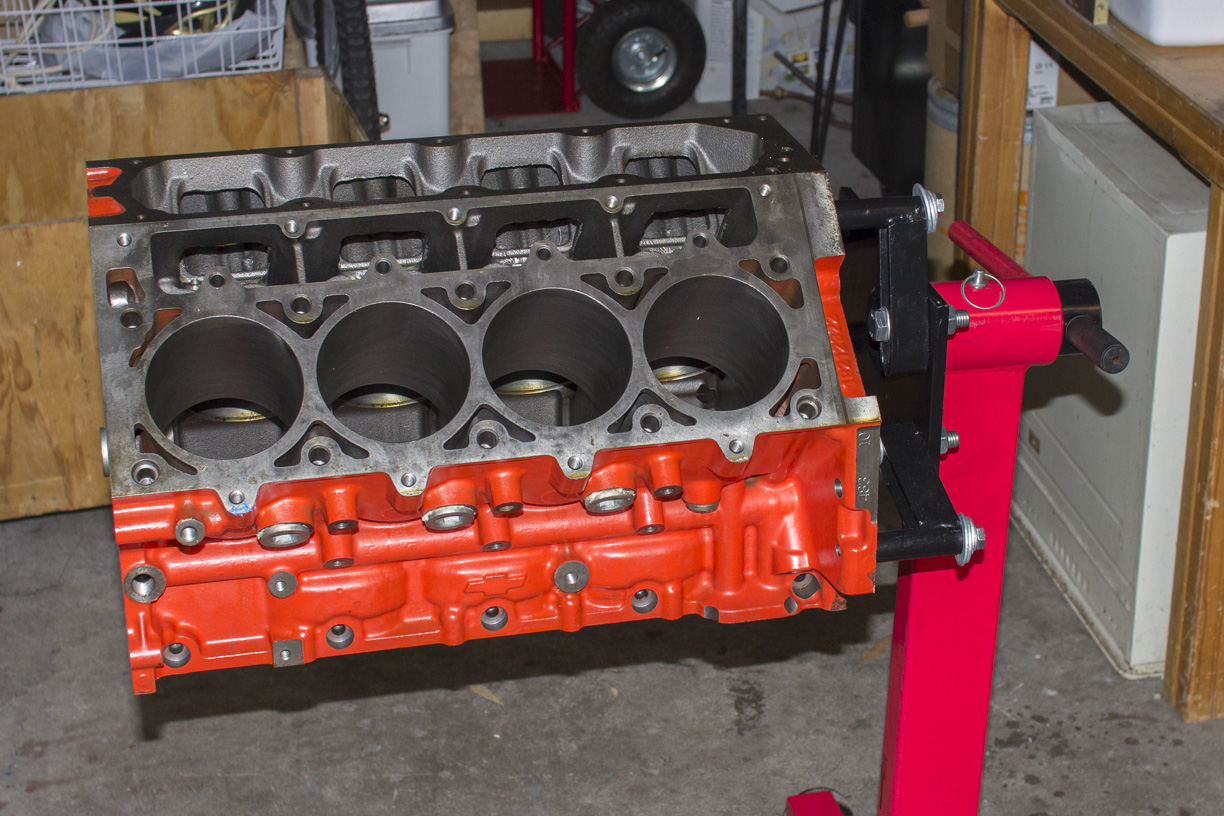

So, first things first I need to get the heavy bastard out of the crate and onto the engine stand. This little gizmo made the job easy.

Done! Ready to put the crank in. Flipped the block and removed the factory main bolts and caps.

Mmmm dowels...

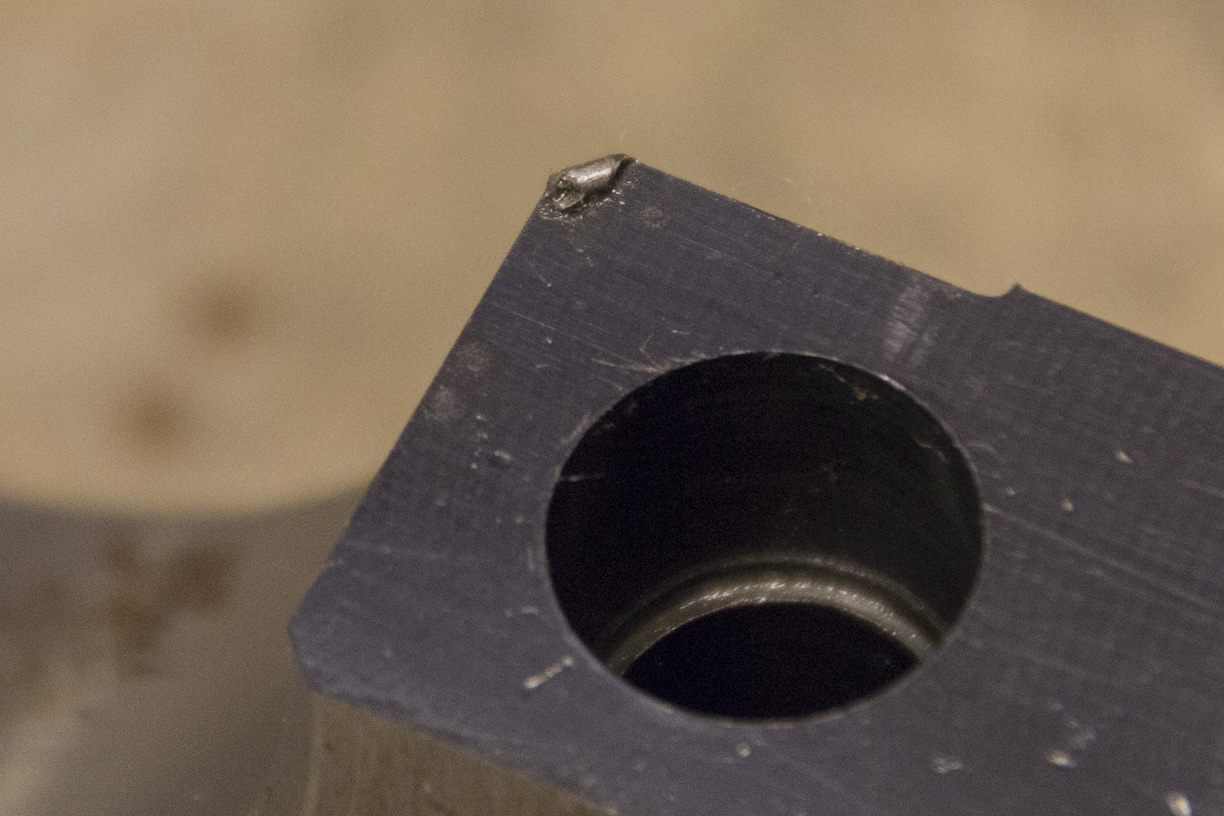

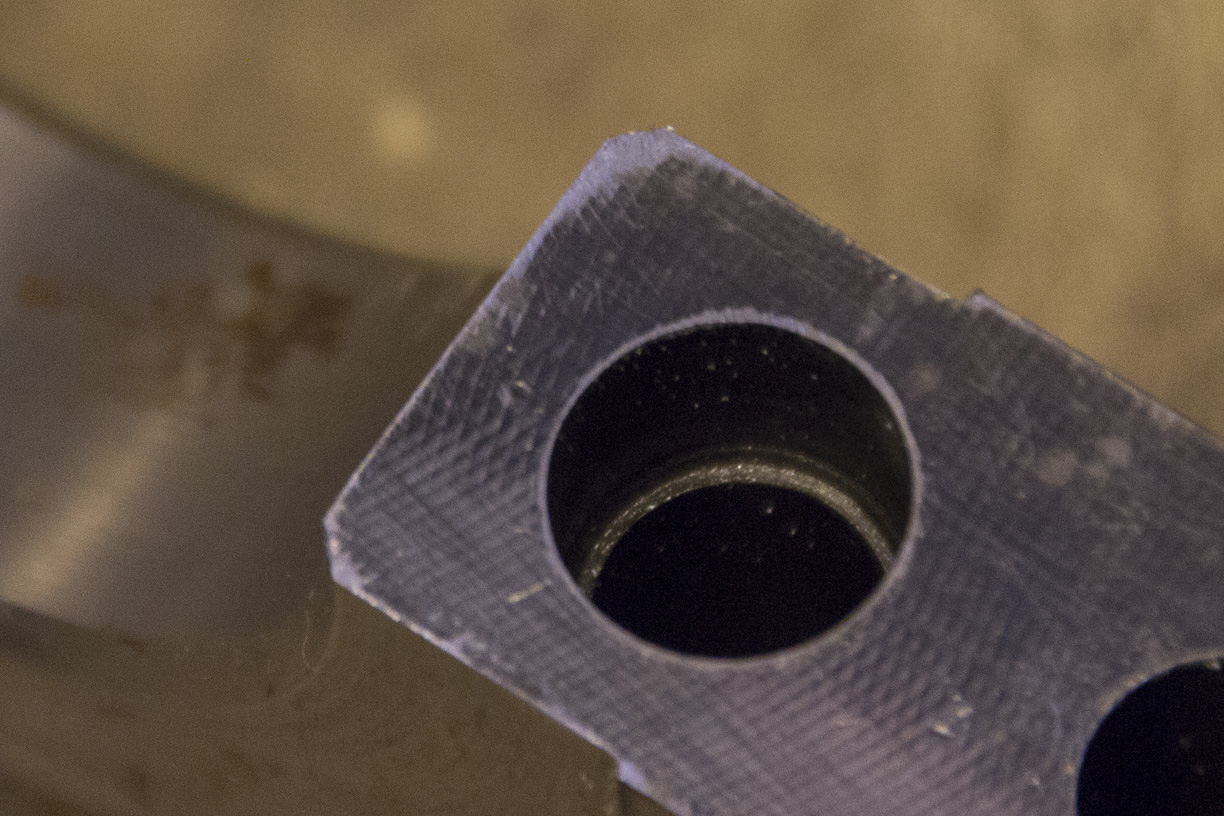

3 of 5 the caps had burs on them which would stop them seating correctly, all in the same position. A little work with the diamond file cleaned these up.

Then I went over the surface area with some emery paper to remove any little specs of rust which had formed.

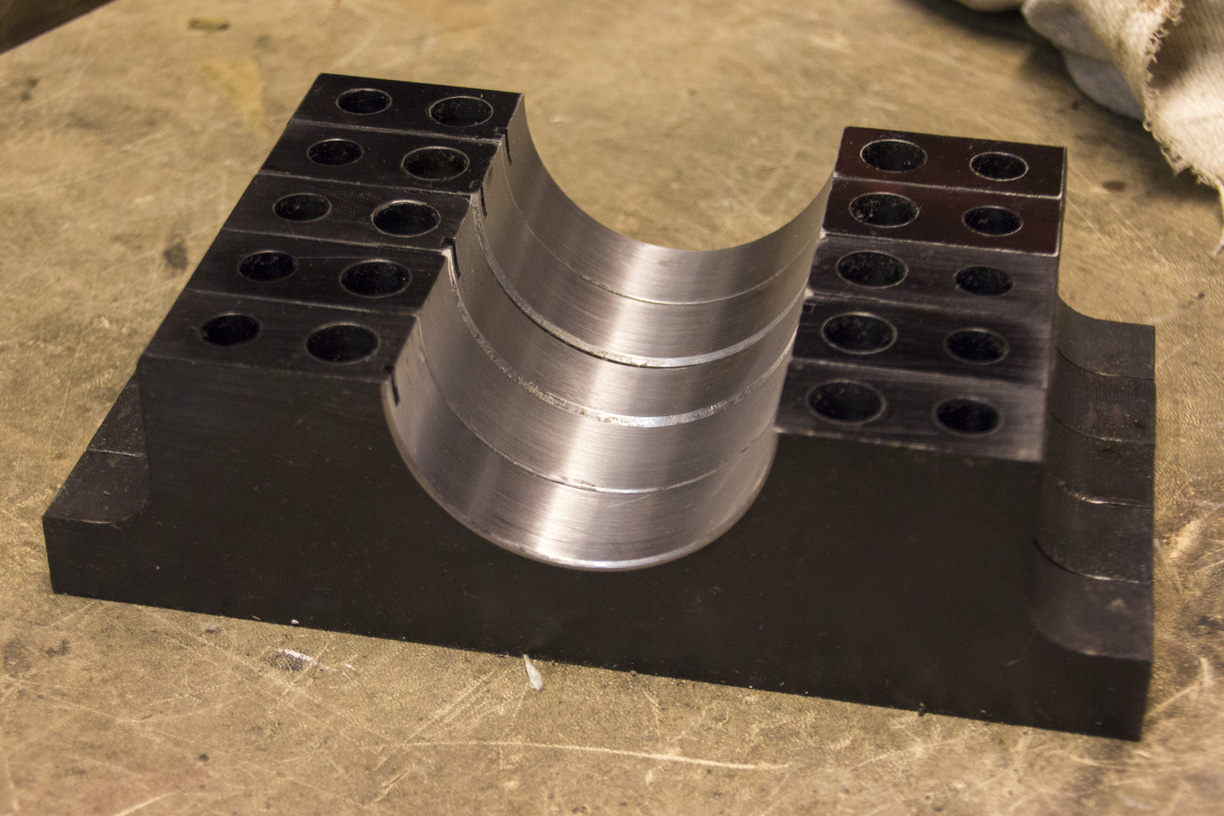

Mmmm billet...

Put the bearings in. Cleaned and rested the crank in dry and added some Plastiguage. Measured the clearances and found about 0.0008" for all. This is wayyy too tight, so will need to be machined out to achieve the desired 0.0025-0.0030" clearance I'd like.

Removed the Plastiguage, cleaned the bearings and added some assembly lube. Put the crank back and torqued down the caps to spec. When torqued, the clearance is too tight to allow the crank to turn by hand, which won't help me with the next stage. Loosened off all of the mains to just over finger tight, which allowed me to turn the crank.

Cleaned up a couple of pistons and installed. Measured the deck to piston clearance which appears to be about 0.0021-0.0022".

Also went through and gapped all of the rings to suit. 0.0022" for the top ring, 0.0014" for the bottom ring, as per Total Seal recommendations.

Tomorrow I'm going to try getting the block back to the machine shop to do the rest of the job. Hopefully it wont take too long!