lozzah666

New Member

- Joined

- Aug 5, 2009

- Messages

- 6

- Reaction score

- 0

- Points

- 0

- Members Ride

- VT Acclaim

Just had heads on VT done up & replaced them ourselves. Engine is running fine, but car has shredded two serpentine belts in quick succession (original & then new replacement).

The belt is disintegrating longitudinally and there is a strange mark along the back of the whole belt where it is tearing. However, we can’t find anything rubbing it there, so maybe it is some sort of flexing or misalignment problem.

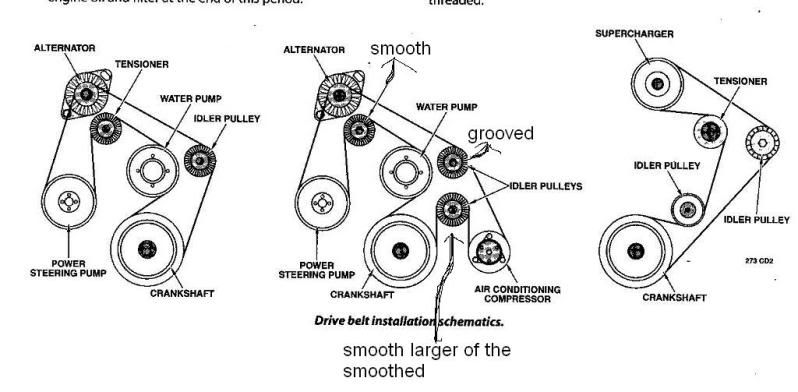

We don’t believe that the belt has been installed in the wrong grooves as we took great care installing the second belt (brand new) since we believed that maybe that was what went wrong with the first.

During the head replacement we took the opportunity to replace the bearings in the idler pulleys so that is a highly likely source of the problem – maybe an omitted spacing washer or something creating a misalignment.

We replaced the idler on the tensioner arm with a new plastic unit but installed a large cupped washer that came with it around the wrong way & the washer got bent up. I believe the washer is a protective shield for the idler bearing. Since it didn’t seem to play a role in the actual fixing of the pulley (spacing for instance), & the pulley is fairly cheap and easy to replace anyhow if the bearing fails early, we decided to just leave it off – maybe we misunderstand what the washer does (it’s probably called an ‘Anti Belt-Shred Washer LOL).

We have checked that all the idler pulleys are rotating fine and also the air conditioner pulley, power steering pulley and alternator pulley are all free to rotate OK. All the pulleys look to be in alignment - visually at least. Is there some way of measuring more accurately though.

We believe the belt orientation is right. Grooves are facing inward at the alternator pulley and outward at tensioner pulley. Around the other way wouldn’t make sense anyway.

Another possibility is that maybe we got two of the idler pulleys mixed up (not even sure if this is possible).

They are installed as follows:

1. Small plastic one (with grooves) is installed at idler arm

2. Small metal one (without grooves) is installed at top right of engine (looking from front) displacing the belt run between the air conditioner pulley and the alternator pulley

3. Larger metal one (without grooves) is installed at lower right of engine (looking from front) between the harmonic balancer pulley and the air conditioner pulley to increase the belt-wrap around both of those pulleys.

The only other thing we can think of is that maybe the power steering pump is seizing or overloading the belt. The pump is in a bad state of repair (leaking, noisy, not assisting steering at all) and both times that the car has shredded the belt have been soon after cornering. However, the problems with the power steering pump were pre-existing and so although the pump may be contributing to the problem, I do not believe it is causing it.

Any suggestions anyone?

The belt is disintegrating longitudinally and there is a strange mark along the back of the whole belt where it is tearing. However, we can’t find anything rubbing it there, so maybe it is some sort of flexing or misalignment problem.

We don’t believe that the belt has been installed in the wrong grooves as we took great care installing the second belt (brand new) since we believed that maybe that was what went wrong with the first.

During the head replacement we took the opportunity to replace the bearings in the idler pulleys so that is a highly likely source of the problem – maybe an omitted spacing washer or something creating a misalignment.

We replaced the idler on the tensioner arm with a new plastic unit but installed a large cupped washer that came with it around the wrong way & the washer got bent up. I believe the washer is a protective shield for the idler bearing. Since it didn’t seem to play a role in the actual fixing of the pulley (spacing for instance), & the pulley is fairly cheap and easy to replace anyhow if the bearing fails early, we decided to just leave it off – maybe we misunderstand what the washer does (it’s probably called an ‘Anti Belt-Shred Washer LOL).

We have checked that all the idler pulleys are rotating fine and also the air conditioner pulley, power steering pulley and alternator pulley are all free to rotate OK. All the pulleys look to be in alignment - visually at least. Is there some way of measuring more accurately though.

We believe the belt orientation is right. Grooves are facing inward at the alternator pulley and outward at tensioner pulley. Around the other way wouldn’t make sense anyway.

Another possibility is that maybe we got two of the idler pulleys mixed up (not even sure if this is possible).

They are installed as follows:

1. Small plastic one (with grooves) is installed at idler arm

2. Small metal one (without grooves) is installed at top right of engine (looking from front) displacing the belt run between the air conditioner pulley and the alternator pulley

3. Larger metal one (without grooves) is installed at lower right of engine (looking from front) between the harmonic balancer pulley and the air conditioner pulley to increase the belt-wrap around both of those pulleys.

The only other thing we can think of is that maybe the power steering pump is seizing or overloading the belt. The pump is in a bad state of repair (leaking, noisy, not assisting steering at all) and both times that the car has shredded the belt have been soon after cornering. However, the problems with the power steering pump were pre-existing and so although the pump may be contributing to the problem, I do not believe it is causing it.

Any suggestions anyone?