EYY

Well-Known Member

- Joined

- Mar 6, 2011

- Messages

- 5,761

- Reaction score

- 2,046

- Points

- 113

- Location

- Vic

- Members Ride

- VS Statesman

What exactly are your goals and why do you want to achieve them?

Is this in prep for future mods? Or just because it's something you want to do?

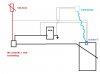

If you're wanting the water for top end cleansing and fuel economy, connecting it via a drip feed will work very well. At cruise (high manifold vacuum), it will be sucking in water. At WOT, it won't be sucking in the water anywhere near as much since the manifold vacuum is low. In the case you're driving with your foot flat to the floor, you don't care about your economy anyway.

Ari offers some really good advice too. Look further into some of is suggestions.

Is this in prep for future mods? Or just because it's something you want to do?

If you're wanting the water for top end cleansing and fuel economy, connecting it via a drip feed will work very well. At cruise (high manifold vacuum), it will be sucking in water. At WOT, it won't be sucking in the water anywhere near as much since the manifold vacuum is low. In the case you're driving with your foot flat to the floor, you don't care about your economy anyway.

Ari offers some really good advice too. Look further into some of is suggestions.